KEY FACILITIES |

HIGHLIGHTS |

| FACTORY AREA |

Our workshop’s floor area is about 43,000 square feet and the cover area of about 33,000 square feet. It equipped with 2 units of 20 Ton + 10 Ton, 1 unit of 10 Ton + 10 Ton, 2 units of 10 Ton SWL Overhead Mobile Cranes of 6M Crane Hook Height and 1 unit of 20 Ton, 1 unit of 10 Ton and 1 unit of 5 Ton SWL Overhead Mobile Cranes of 9M Crane Hook Height.

|

| WELDING |

The welding processes commonly used by us are Submerged Arc Welding, Tungsten Inert Gas Welding, Metal Inert Gas Welding and Shielded Metal Arc Welding. |

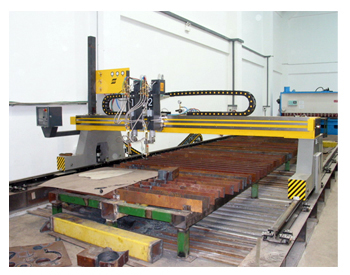

| METAL CUTTING |

The usual Oxy-acetylene and Disc Cutters. We have Plasma Arc Cutting Machines to cut stainless steel up to thickness of 30mm. Our “CNC” profile/gantry cutting machines cuts shapes and square plates accurately. |

| SHEARING |

Able to perform shearing of plates for sizes up to 16mm thick and 6 meter in length. |

| ROLLING |

Plates able to perform in-house rolling up to the following specifications:

i) 10 feet length & 2 inch thick (High Tensile).

ii) 10 feet length & 1 inch thick (Hardox / Weldox).

|

| BENDING |

Forming of cones, small radius bends and thick section are done with our 550 Ton Hydraulic Presses. |

| FORMING |

Plates of various sizes and thickness are able to perform with our 400 Ton Hydraulic Press. |

| DRILLING |

Holes of various thickness (drill bit subjected to market stock) can be drilled up to Dia.50mm. |

A) |

WELDING EQUIPMENT

|

- 1 Unit 4M x 4M Column & Beam Submerged Arc Welding.

- 18 Units of Shielded Metal Arc Welding.

- 12 Units of Metal Inert Gas Welding.

- 1 Unit of Tungsten Inert Gas Welding.

|

B) |

CUTTING EQUIPMENT

- 1 Unit 2-Torch Profile/Gantry Flame Cutting Machine.

- 4 Units Tractor Auto Flame Cutting Machine.

- 3 Units High Speed Disc Cutter.

- 2 Units Circular Flame Cutting Machine.

- 1 Unit Plasma Arc Cutting System.

- 2 Units of Oxygen 7 Acetylene centralized with distribution point throughout the workshop.

- 1 Unit of Shearing Machine.

|

C) |

LIFTING & POSITIONING EQUIPMENT

|

- 2 Units 20 Ton + 10 Ton Overhead Mobile Crane.

- 1 Unit 20 Ton Overhead Mobile Crane.

- 1 Unit 10 Ton + 10 Ton Overhead Mobile Crane.

- 2 Units 10 Ton Overhead Mobile Crane.

- 1 Unit 5 Ton Overhead Mobile Crane.

- 1 Unit 4 Ton Forklift.

|

|

|

| D) |

BENDING / FORMING EQUIPMENT

- 1 Unit 550 Ton Bending Machine.

- 1 Unit 400 Ton Hydraulic Press.

|

| E) |

ROLLING EQUIPMENT

|

- Up to thickness of 2 inch x length 10 feet

(High Tensile Grade).

- Up to thickness of 1 inch x length 10 feet

(Hardox / Weldox Grade).

|

| F) |

MISCELLANEOUS EQUIPMENT

|

- Hydraulic Hole Punches.

- Pedestal & Magnetic Drills.

- Grinders (Air & Electrical).

- Jacking Tools.

- Rotary Air Compressor

(Centralized with distribution Point throughout the workshop).

|